Rotech

Keg Line Monitoring System

Have you got a keg cleaning/filling line ?

Rotech’s Keg Line Monitoring is a ‘Must Have’ essential tool. A world leader in electronic keg systems, Rotech offer by far the easiest use on the line and the most user-friendly and advanced software.

The Queen’s Awards for Enterprise: International Trade 2019 winner

・ User-centred design and software

・ Developed by Rotech in response to Brewery demands

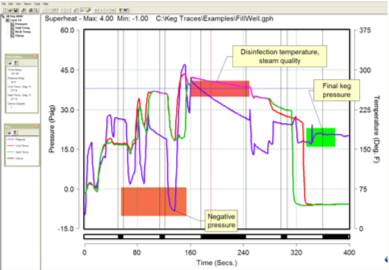

・ Shows exactly what is happening inside the keg

・ In regular brewery use in over 60 countries

・ Setting the de facto standard for keg line monitoring

How Do Rotech Monitor?

The Key is to know exactly what is happening inside your kegs during washing, disinfection and fill. This is the only place it matters, and if you don’t know, you are literally flying blind.

No MIS/SCADA can go inside the keg. Outside measurements cannot hope to tell if wash liquors are pooling, if disinfection steam is saturated in the keg, what the dynamic counter-pressure is during fill, how much fobbing (frothing) there is — and why; nor many other crucial in-keg parameters.

But this information is essential for routine assurance of hygiene and for fast, quiet, gas-balanced fills — also for pinpointing faults, eliminating process delays and improving energy efficiency.

Pouring the perfect pint – everytime, means you need to monitor both your keg and the contents.

Rotech is a world leader in electronic keg systems. We offer unique features that are by far the easiest use on the line, together with the most user friendly and advanced software.

Rotech are proud to work with the following brands and companies…

Our Services

Good Keg data

Rotech has specialised in keg and racker monitoring since 1988. We have seen just about every problem there is in keg cleaning and filling. We have thousands of records, good and bad, from virtually every type and size of keg and filling line, from all over the world.

Easy-to-read Results

Clear and Confident Action

Get In Touch

Call Us

Send a Message

This contact form below will email us directly.

In trying to avoid spam emails, we use reCaptcha (v3) to minimise the number of non-authentic and inappropriate emails.

For the purposes of GDPR, by pressing Submit, you consent to having this website store your submitted information so we can respond to your enquiry.

Frequently Asked Questions

Why monitor?

Do you know what is happening inside your keg on each head of your filler?

For example:

- Are you using excessive detergent for rinses?

- Are there unintentional pools in the keg during washing?

- Are you using more energy than you need?

- If you steam disinfect — is your steam saturated, and is your disinfection cycle adequate?

- Have you got filling, frothing/fobbing, or gas balance problems with the beer?

- Are there unnecessary delays that could be reduced to fill more kegs per hour?

These are just some of the issues vital for fast, efficient, and hygienic operation of the line.

How do you use it ?

- Put the keg through the line as normal, including filling. It logs every cycle, every head.

- Recover from the outfeed/decant; send run information to the PC when you are ready.

- View and analyse results with powerful

user-friendly software.

The Rotech Keg will tell you everything about your keg filling line — including its energy efficiency, whether it is properly sanitising kegs, if your utilities consumption is excessive, if and why you have filling problems, how to increase your throughput without risk to quality, and generally how closely performance matches program targets. It is an indispensable tool for tracking down engineering problems, persistent or intermittent.

Is there much fobbing (frothing) ?

Is the meter working ?

What are fill times? Is the fill profile control working?

The Rotech Keg, with its unique level sensor, continuously reads actual liquid contents, and instantaneous rates of filling or emptying. Use these data to check the fill profile, follow cycles of slow-fast-slow fills, measure intermediate and final fill times.